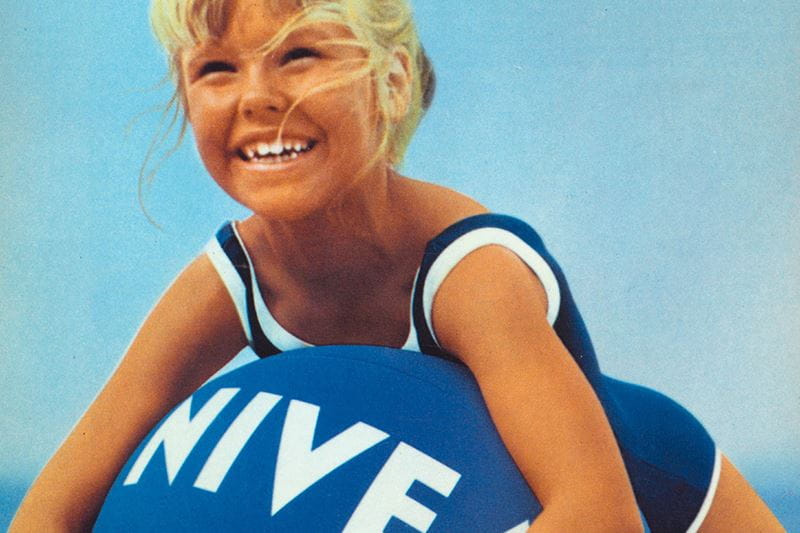

Brand & Company

Learn interesting facts about NIVEA and Beiersdorf.

ABOUT US

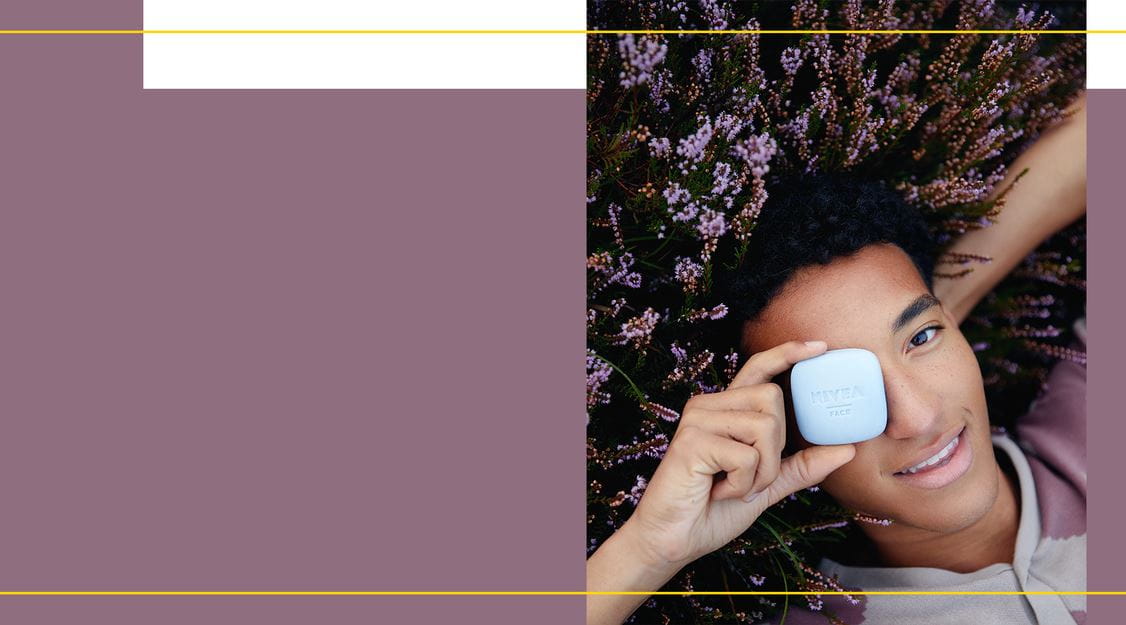

As one of the leading companies in the field of skin care – with more than 130 years of experience – our products always cater for the needs of our consumers, who place a great deal of faith in us. Learn more about us here.